“ESC” Brand Products

DMSMS / Obsolescence Solutions

Manufacturing Services

ES Components has been serving the Aerospace, Space, Defense, Medical, and Industrial Markets since 1981, offering "ESC" brand products, DMSMS solutions, and comprehensive manufacturing services. With assembly, packaging, screening, and testing conducted in labs certified by both the DLA and ES Components, our company ensures high-quality standards and reliability for its clients in critical sectors.

Let’s Get In Touch…

“ESC” Brand Products and Turn-Key Custom Assemblies

MIL-PRF-19500, 38534, 38535 equivalent

All hermetic packages, flows, and QCI

Obsolescence solutions

Siliconix Inside – Hermetic Siliconix products from ES Components

Custom hirel assemblies: monolithic or arrays in hermetic DIP or LCC; multi-chip power modules

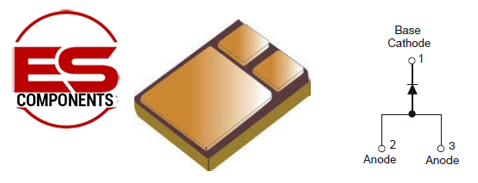

Convert plastic diodes to hirel hermetic SMD device using same DIE

ES Components ESx8EU8H03 Hermetic

8A / 300V Hyperfast Diode

• Hermetic U8 (SMD.2) SMT package with

MIL-PRF-19500 equivalent screening

• Bare Die with element evaluation per

MIl-PRF-38534 (if required)

• Hermetic alternative to Vishay commercial

8ETH03-M3 device

• Engineering Model Units and Die available

from ES COMPONENTS Stock!

-

Using World’s largest diverse inventory of Legacy Bare Die.

-

Custom Packaging Using Our Legacy Inventory That Includes Over 40,000 Components

Per Customer drawing and / or per MIL-PRF-19500, 38534, 38535 Process Flows

(Tin/Lead) Plating

Recertification of Out-of-Date Material

Radiation Hardness Analysis

Counterfeit Analysis per DLA, QTSL, and AS6081

-

We can up-screen devices to more stringent specifications:

Do you need your DMSMS product custom configured to meet your specific specifications? We can process your DMSMS order in wafer form, bare die form, or custom packaged and screened to meet your specific SCD (source control drawing) requirements. All parts are carefully protected from environmental and electrical damage with vacuum sealed aluminum bags that are segregated by individual lot numbers. Military screening, burn-in, and testing can be provided as needed.

Element Evaluation Based On Customer’s Requirements

Element Evaluation can be per the customer’s specific Source or Specification Control Drawing (SCD), Military Performance Specifications such as MIL-PRF-38534, MIL-PRF-38535, MIL-PRF-19500 or other pertinent Military specifications. ES Components performs this service for many of our customers, which entails building a sample of the die into a package and can include Environmental Screening, Electrical Screening, Burn-In, Life Test, Wirebond Pull Test, Scanning Electron Microscope (SEM) Analysis, and Destructive Physical Analysis (DPA). This step can be used to avoid counterfeit devices by verifying the specific lot or wafer ‘s performance in addition to Visual Inspection. The records for Element Evaluation are kept by lot (by wafer for Class K) and fully traceable by shipment. All records are kept for a minimum of 7 years. To date, ES Components has kept all of our historical records.

Services Offered:

Per ES Components Spec# MIL-PRF-38535, MIL-PRF-19500, and MIL-PRF-55310 Process Flows

(Tin/Lead) Plating

Recertification of Out-of-Date Material

Radiation Hardness Analysis

Counterfeit Analysis per DLA, QTSL, and AS6081

-

When the availability of semiconductor devices is limited to commercial or automotive grade components, ES Components can provide “equivalent” Mil Spec assembly, screening, and quality conformance inspection. This is accomplished by either up-screening assembled devices or assembling devices into hermetic packages when wafers or die are available.

There are a myriad of “building block” semiconductor devices that have supported the high reliability market for more than 60 years by virtue of “MIL SPECS” such as MIL PRF 19500, 38510, 38534, 38535, and others. These products are typically fabricated, assembled, screened, and quality conformance tested per these controlled “Mil Specs” and are typically identified with a JAN prefix (for Discrete devices) or a /883B suffix (for Integrated Circuits). The long history and established reliability data make these devices the “go-to” products for new platform designs.

However, the vast majority of semiconductor devices in the market today are only available as commercial or automotive grade devices that do not meet these stringent Mil Spec requirements, particularly regarding the mitigation of “infant mortality” failures, which is accomplished by performing 100% high temperature reverse bias (HTRB) and/or 100% burn-in to the production lot.

The good news is, commercial or automotive semiconductors can up-screened to “equivalent” Military or Space grade on a lot by lot basis by performing Mil Spec assembly, screening, and quality conformance inspection, using established Mil specs as the guide.

Up-screening can be accomplished by one of 3 options:

1. Procure the hermetic commercial part and up-screen as needed.

2. Procure the plastic commercial part and up-screen as needed, omitting all test requirements for hermeticity.

3. Procure the device in die or wafer form, assemble in the appropriate hermetic package, and up-screen as needed.

An issue with options 1 or 2 is that traceability is limited to the established assembly “date code” only, not diffusion lot traceability (required for Military grade) or wafer traceability (required for Space grade). A date code can include any number of diffusion runs, since this is not a requirement for commercial or automotive grade devices. A date code is typically limited to the assembly sealing of a given population of devices over a 1 week period (maybe longer). Another service offered by ES Components is sorting any given production “lot” of commercial / automotive devices by date code and up-screening each sub-lot as needed.

Once the production lot and screening requirements are defined, ES Components utilizes the capabilities of DLA certified assembly, screening, and QCI Sample Test Labs to provide equivalent Military or Space grade devices per applicable Mil specs or whatever custom flow is required by the end user. We fully support “custom” requirements, and provide full logistics support throughout the process. You place one PO and receive finished goods units.

If Radiation Tolerance is an issue in the application we can provide hermetically sealed samples, serialized and with test data, suitable for testing by the user for application specific radiation performance. Note that Radiation Tolerance can vary from wafer to wafer, so traceability becomes a critical factor, and the Customer assumes lot jeopardy for the results. There is no “fail” criteria.